本多産業とは?

フッ素樹脂製品の

製造・開発メーカーです

本多産業は、フッ素樹脂製品の製造・開発メーカーです。

フッ素樹脂は耐熱性・非粘着性・すべり特性・耐薬品性などの優れた特性を持ち

様々な産業分野で重要な役割を果たしています。

1973年の設立以来、半世紀に渡り、

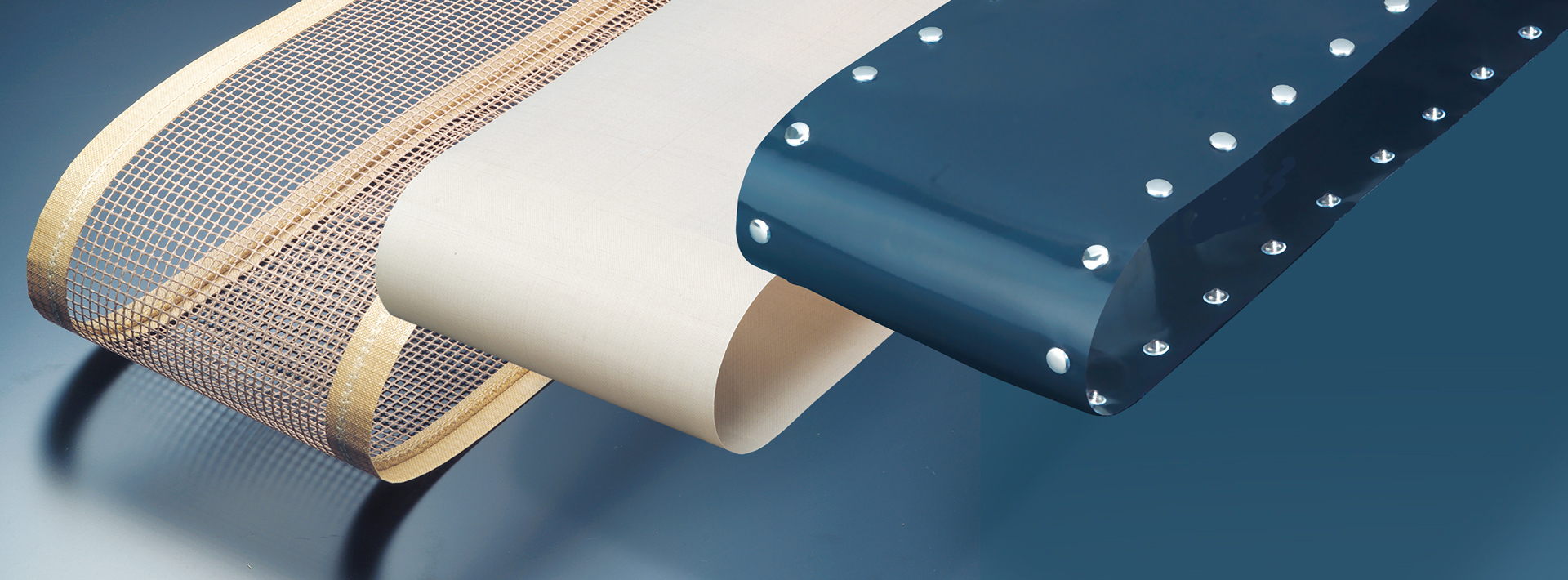

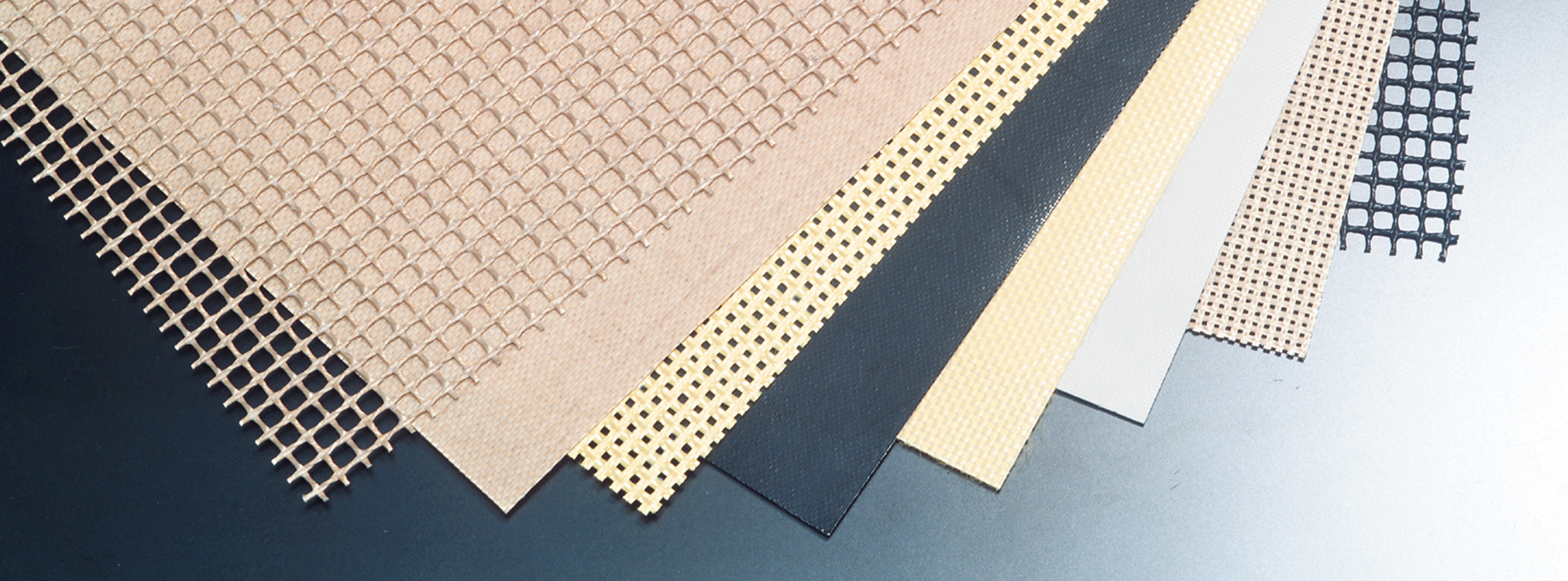

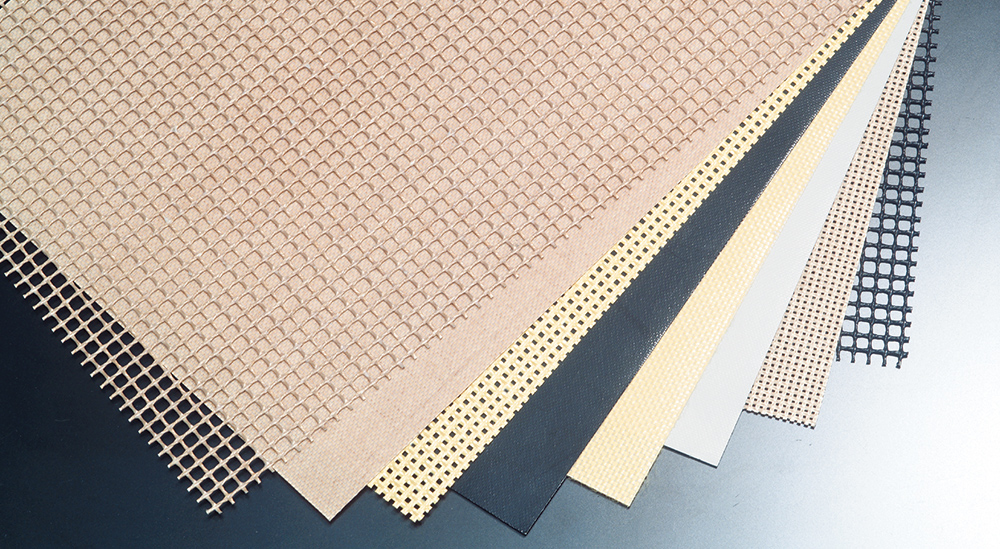

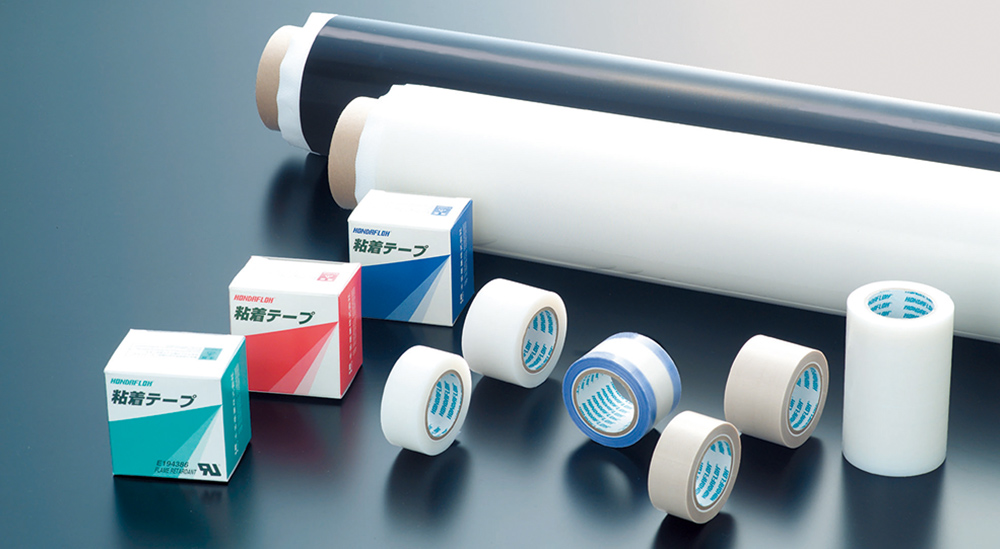

フッ素樹脂コーティングファブリック・コンベアベルト・粘着テープなどを開発・製造して参りました。

これからもフッ素樹脂製品でものづくりを支える企業として、

お客様のニーズにお応えしてまいります。

H

O

N

D

A

S

A

N

G

Y

O

事業内容WORKS

本多産業では製品の開発・製造・検査・販売・施工までを一気通貫で実施致します。

- 開発

- 製造

- 検査

- 販売

- 施工

ユーザー担当者様のお困り事

- フッ素樹脂ベルトを購入したのにすぐ壊れてしまったとお悩みの資材部担当者様

- 販売後にメンテンテナンスもきちんとやってくれる業者を探されている購買担当者様

- 製品の歩留まりが悪く生産性でお悩みの生産管理者様

本多産業がお悩みにお応えします!

弊社の製品はこんな業界で使用されています

弊社の製品は多種多様な業界で使用されています。下記その一部をご紹介致します。

食品メーカー様

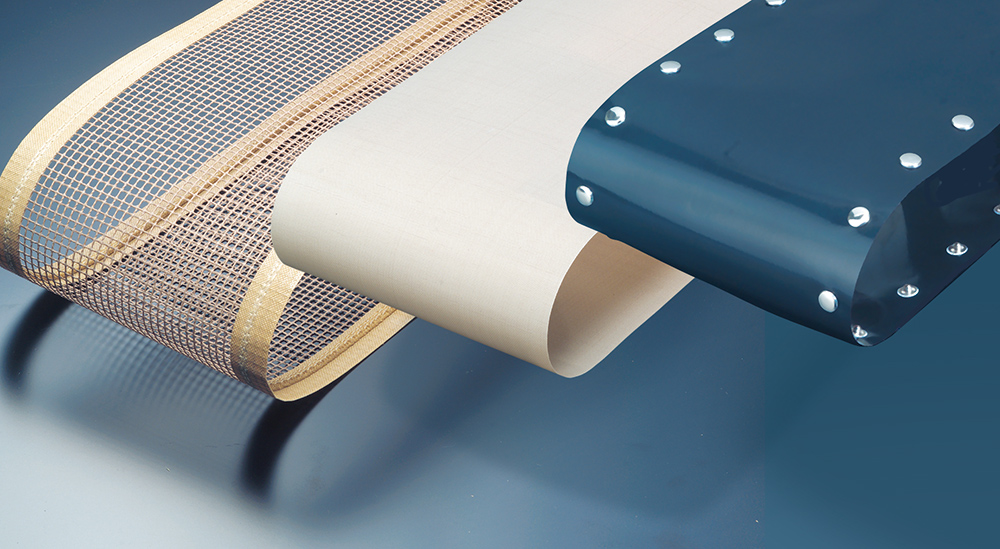

食品がベルトにくっつかないようにしたい等のご要望を叶えるフッ素樹脂ベルト等を積極的に採用いただいております。食品の種類によって、ベルトタイプも異なります。通気性重視の場合はメッシュタイプで、耐湿熱性を優先する場合、アラミドクロスの基材を使用する場合が多いです。

機械メーカー様

エンドクライアント様ご指定の要件を満たす機械設計に当社の耐熱性の高いコンベアベルトが多く採用されています。フッ素樹脂ベルトの主な欠点として、「蛇行しやすく調整が難しい」、「ベルト自体の剛性が弱く、傷つきやすい」があげられます。

そこで、本多製ベルトは蛇行防止策として、自社手法でベルトの裏面に特殊ライナーを装着します。他のガイドに比べ屈曲性にとみ、小プーリ径に対応できます。

様々な業界での使用例があり好評を頂いております。

NEWS新着情報

- 2024.01.15

- NEWS 繰り返し使える-HONDAFLOHクレープシート

- 2023.12.27

- NEWS 面倒な食器洗いのいらない HONDAFLOH舟皿

- 2023.12.12

- NEWS ホンダフローガーデンシートのご紹介

- 2023.07.03

- NEWS 表面が粗い粘着テープの新製品!

- 2023.02.01

- NEWS 再放送>>テレビCM~